OPTIMAL STABILIZATION OF THE

KNEE JOINT

Through the cooperation with specialized medical experts, physiotherapists, and athletes, it has been possible to develop a truly new support and provision concept for the knee joint.

K-COM?

»

A K-COM knee brace can be beneficial for various reasons.

1. In cases of chronic joint instability, to avoid secondary injuries (meniscus tear, cartilage defect) and to prevent or delay arthrosis of the knee joint in the long term.

2. In extreme cases of knock-knees or bow legs, to correct the axial deviation and thus relieve the overstressed part of the joint.

3. For chronic knee joint pain in everyday life, which severely restricts work or leisure activities.

4. As preventive treatment for high-risk sports.

A K-COM knee brace can be beneficial for various reasons.

1. In cases of chronic joint instability, to avoid secondary injuries (meniscus tear, cartilage defect) and to prevent or delay arthrosis of the knee joint in the long term.

2. In extreme cases of knock-knees or bow legs, to correct the axial deviation and thus relieve the overstressed part of the joint.

3. For chronic knee joint pain in everyday life, which severely restricts work or leisure activities.

4. As preventive treatment for high-risk sports.

KNEE JOINT

»

If the cruciate ligament is torn, the knee joint becomes unstable. The patient typically complains about a feeling of unsteadiness, of the knee joint "buckling" beneath them. Even well-developed musculature can only partially compensate for this instability. Often, further twisting of the knee occurs over time, which can lead to meniscus and cartilage damage due to the lack of stability. Studies clearly show that the risk of arthrosis of the knee joint is significantly increased without a stabilising cruciate ligament. For this reason, unstable knee joints should be surgically treated at an early stage, especially in children and younger and active patients. If the cruciate ligament is not operated on, a sturdy brace should be worn during more strenuous everyday activities.

If the cruciate ligament is torn, the knee joint becomes unstable. The patient typically complains about a feeling of unsteadiness, of the knee joint "buckling" beneath them. Even well-developed musculature can only partially compensate for this instability. Often, further twisting of the knee occurs over time, which can lead to meniscus and cartilage damage due to the lack of stability. Studies clearly show that the risk of arthrosis of the knee joint is significantly increased without a stabilising cruciate ligament. For this reason, unstable knee joints should be surgically treated at an early stage, especially in children and younger and active patients. If the cruciate ligament is not operated on, a sturdy brace should be worn during more strenuous everyday activities.

SPORTS EQUIPMENT

»

A higher chance of injury exists in high-risk sports such as motocross, enduro, supermoto, speedway, mountain biking, ice hockey, American football, skiing or kiting. In particular, this applies to the knee joint. A serious knee injury can mean a long period of rehabilitation or even the end of your career.

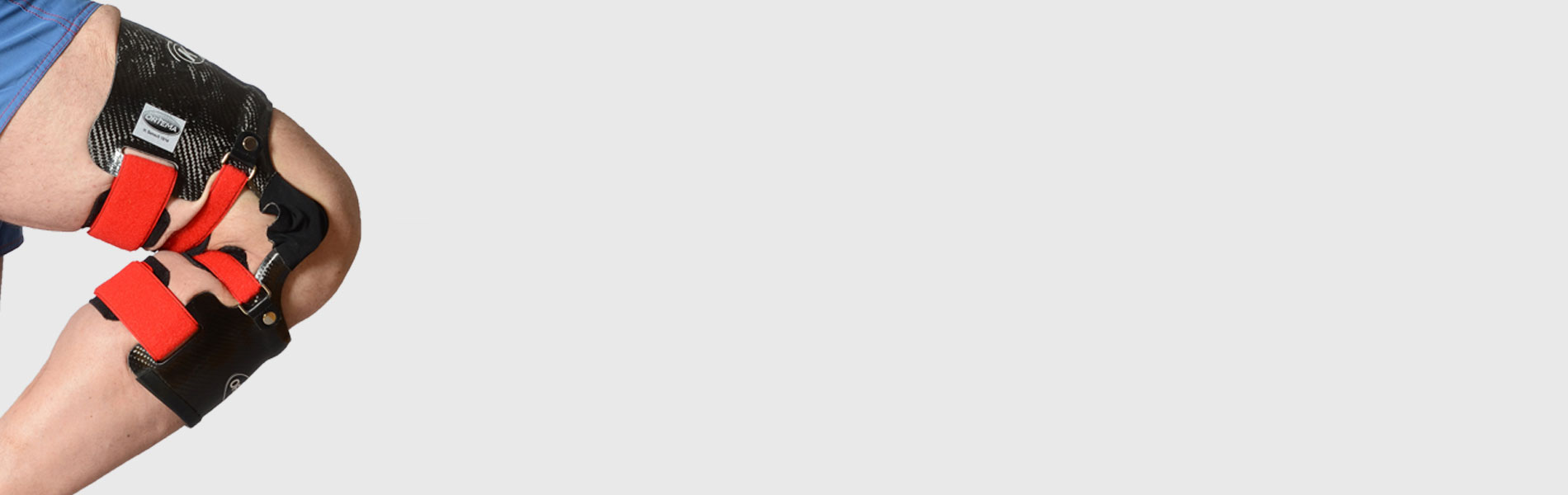

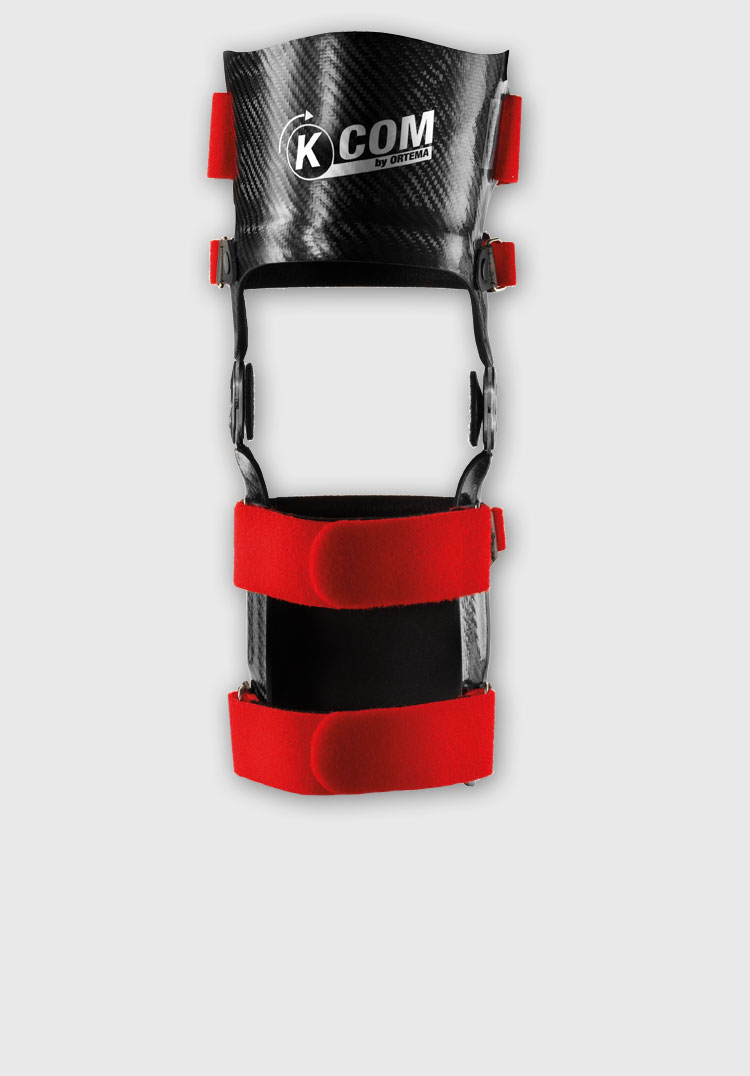

The K-COM knee brace can be used both preventively and postoperatively. This helps to prevent knee injuries or ensure a quicker return to competition. The K-COM combines maximum stability with a perfect fit, extremely low weight and excellent slip resistance. For off-road sports, protection for the kneecap can be added.

A higher chance of injury exists in high-risk sports such as motocross, enduro, supermoto, speedway, mountain biking, ice hockey, American football, skiing or kiting. In particular, this applies to the knee joint. A serious knee injury can mean a long period of rehabilitation or even the end of your career.

The K-COM knee brace can be used both preventively and postoperatively. This helps to prevent knee injuries or ensure a quicker return to competition. The K-COM combines maximum stability with a perfect fit, extremely low weight and excellent slip resistance. For off-road sports, protection for the kneecap can be added.

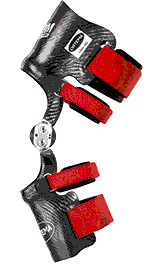

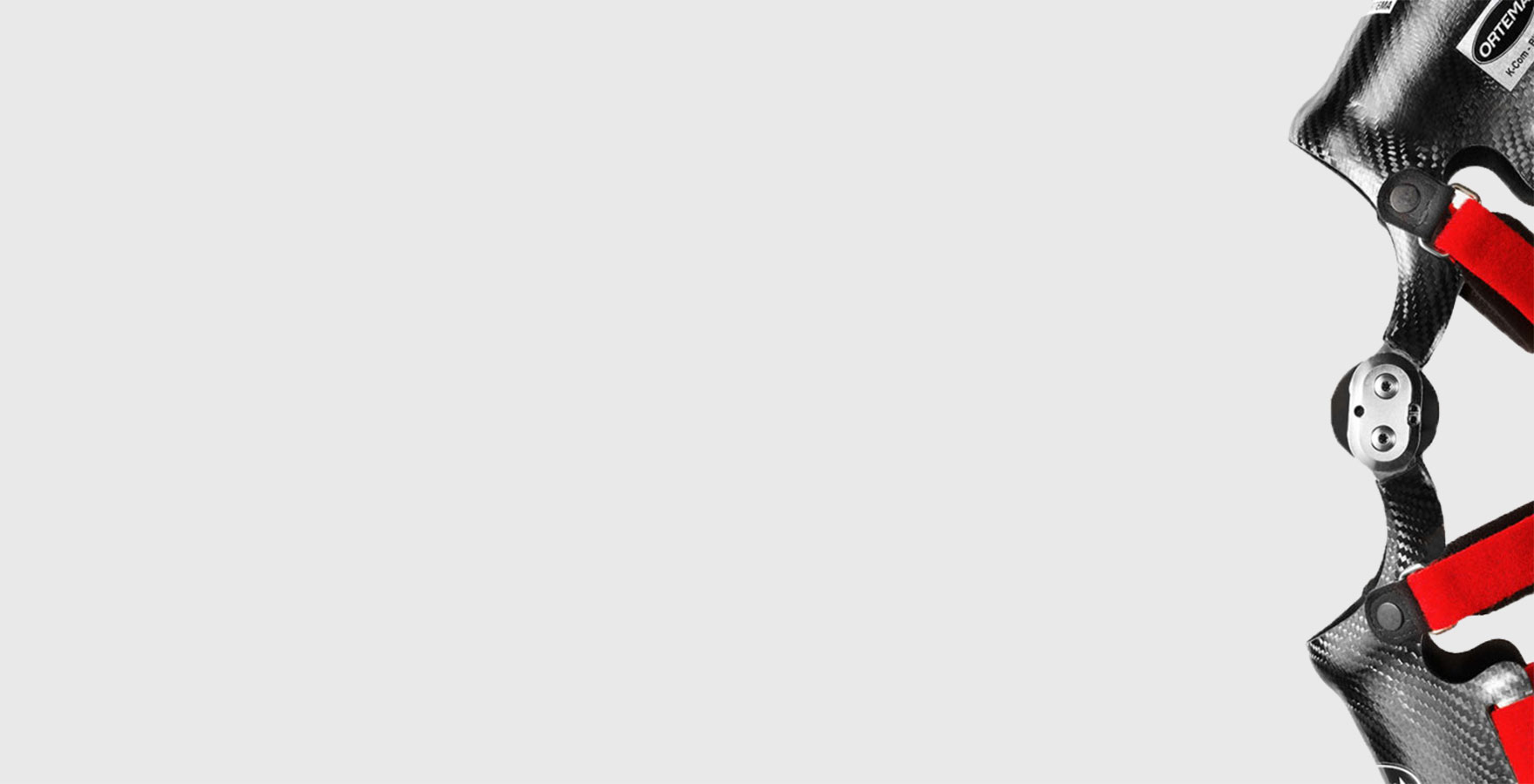

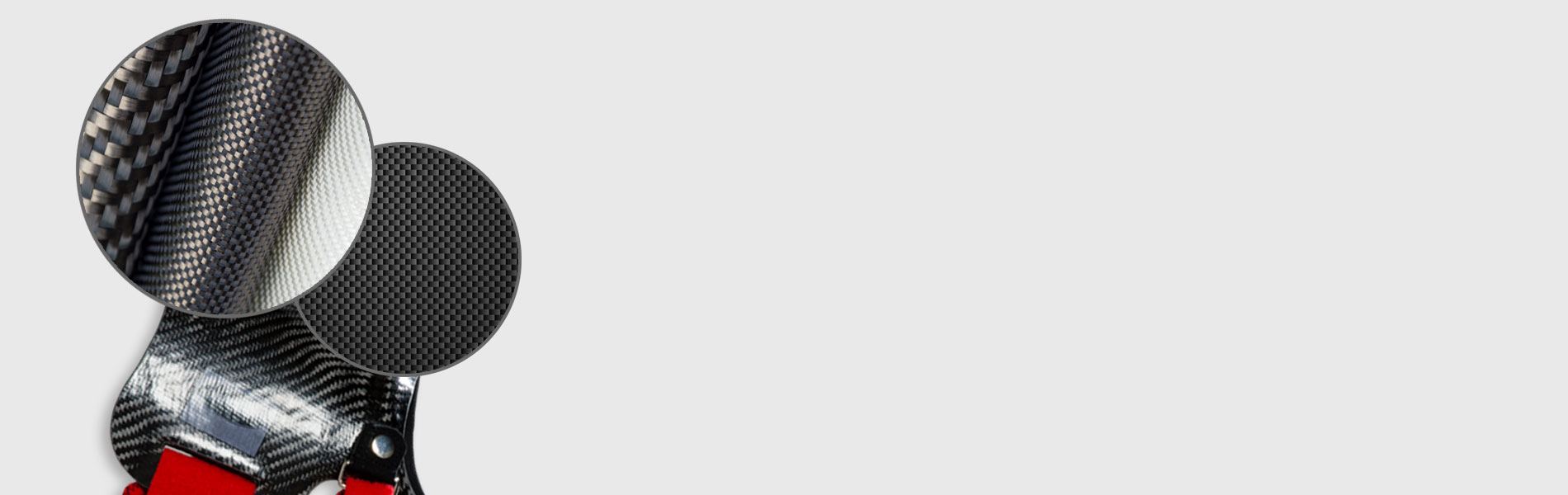

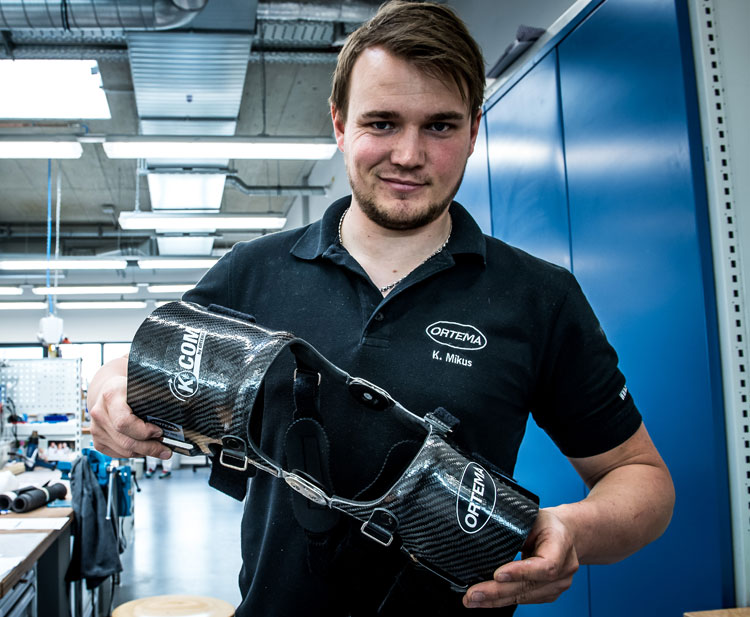

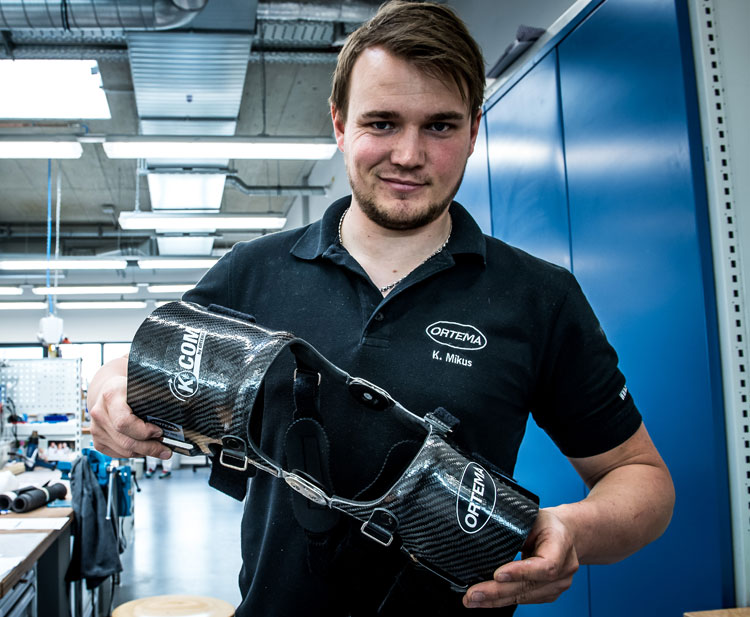

The 100% individually manufactured K-COM fits perfectly - with every movement. The semi-flexible shells take into account muscle play.

With only 1.5 mm thin shells in sandwich construction. This allows the brace to fit under clothing without any problems.

The thin thigh and lower leg shells are manufactured in sandwich construction from carbon and glass fiber. This enables light, flexible and highly stable orthoses.

The materials carbon fiber and titanium are extremely stable despite their low weight. This increases the safety and wearing comfort of the K-COM knee brace made by ORTEMA.

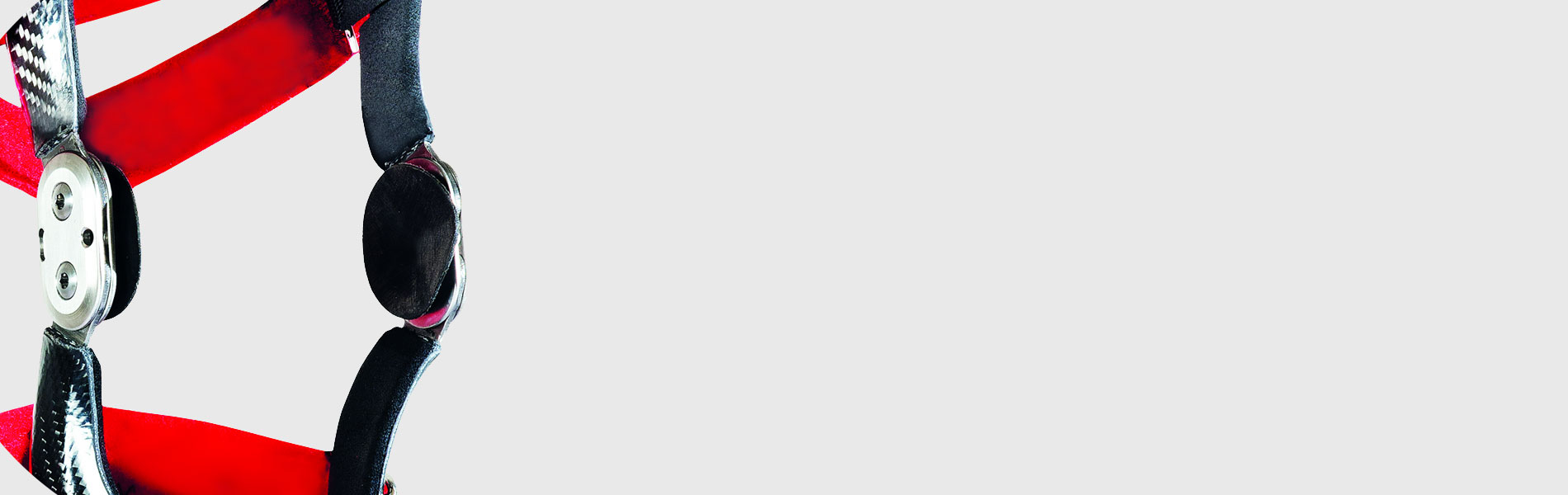

The joints made of titanium and carbon fiber, form a very stable frame construction for perfect guidance and stabilization of the knee joint.

Small inserts can be used to limit the extension and flexion of the joint if necessary.

The 100% individually manufactured K-COM fits perfectly - with every movement.

The semi-flexible shells take into account muscle play.

With only 1.5 mm thin shells in sandwich construction.

This allows the brace to fit under clothing without any problems.

The thin thigh and lower leg shells are manufactured in sandwich construction from carbon and glass fiber.

This enables light, flexible and highly stable orthoses

The materials carbon fiber and titanium are extremely stable despite their low weight.

This increases the safety and wearing comfort of the K-COM knee brace made by ORTEMA.

The joints made of titanium and carbon fiber, form a very stable frame construction for perfect guidance and stabilization of the knee joint.

Small inserts can be used to limit the extension and flexion of the joint if necessary.

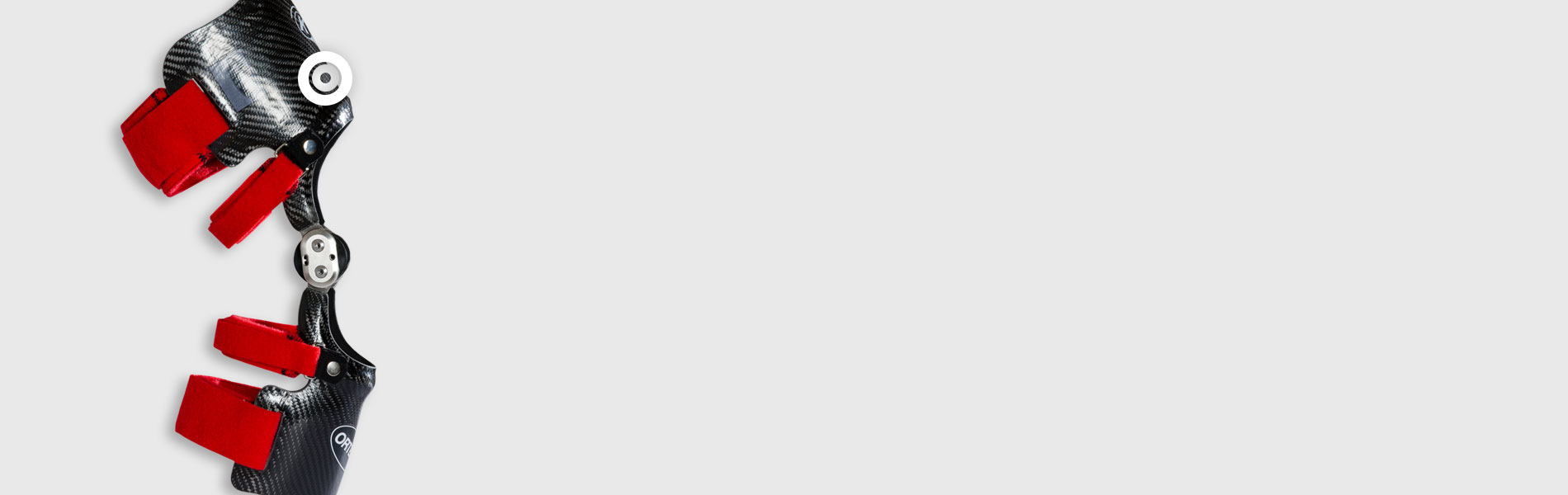

SYSTEM OVERVIEW

The K-COM knee orthosis concept offers different designs for different injuries and diseases. The orthosis design depends on the individual diagnosis and the needs of the patient. The orthosis can be used for stabilization after knee joint injuries, for relief in the case of osteoarthritis or as a preventive measure in sports.

»

The torsion-resistant frame construction offers optimal stabilization to avoid the anterior compartment. This provides preventive protection for the anterior cruciate ligament after injury, after surgery or during sports.

Indication:

Anterior cruciate ligament injury

Meniscus injury and refixation

Injury of the capsular ligament

Cartilage reparations

Early functional stabilization

The torsion-resistant frame construction offers optimal stabilization to avoid the anterior compartment. This provides preventive protection for the anterior cruciate ligament after injury, after surgery or during sports.

Indication:

Anterior cruciate ligament injury

Meniscus injury and refixation

Injury of the capsular ligament

Cartilage reparations

Early functional stabilization

»

This version of the K-COM also avoids the anterior compartment and thus protects the anterior cruciate ligament. However, the shells on the lower leg and thigh are somewhat larger on the inside, thus ensuring even more effective stabilization of the knee joint after complex injuries.

Indication:

Anterior cruciate ligament injury

Rupture of the collateral ligaments (medial/lateral collateral ligament)

Meniscus injury and refixation

Injury to the capsular ligament

Cartilage reparations

Early functional stabilization

Knee endoprosthesis

This version of the K-COM also avoids the anterior compartment and thus protects the anterior cruciate ligament. However, the shells on the lower leg and thigh are somewhat larger on the inside, thus ensuring even more effective stabilization of the knee joint after complex injuries.

Indication:

Anterior cruciate ligament injury

Rupture of the collateral ligaments (medial/lateral collateral ligament)

Meniscus injury and refixation

Injury to the capsular ligament

Cartilage reparations

Early functional stabilization

Knee endoprosthesis

»

A lower leg frame on the back avoids the posterior compartment after an injury to the posterior cruciate ligament. A belt close to the joint in the bending zone promotes a dynamic forward shank motion.

Indication:

Rupture of posterior cruciate ligament

Combination injury with participation of the posterior cruciate ligament

A lower leg frame on the back avoids the posterior compartment after an injury to the posterior cruciate ligament. A belt close to the joint in the bending zone promotes a dynamic forward shank motion.

Indication:

Rupture of posterior cruciate ligament

Combination injury with participation of the posterior cruciate ligament

»

This version is very well suited for older patients with osteoarthritis. The knee joint is optimally guided by a large-area orthosis construction. Closure at the front makes it easier for older patients to put on the orthosis.

Indication:

Knee joints arthrosis

Pangonarthrosis

Genu recurvatum

This version is very well suited for older patients with osteoarthritis. The knee joint is optimally guided by a large-area orthosis construction. Closure at the front makes it easier for older patients to put on the orthosis.

Indication:

Knee joints arthrosis

Pangonarthrosis

Genu recurvatum

»

In the case of a O-legs malposition, the knee joint is overstressed on the inside. This often leads to arthrosis on the inside of the joint.

Indication:

Varus gonarthrosis with axial malalignment

In the case of a O-legs malposition, the knee joint is overstressed on the inside. This often leads to arthrosis on the inside of the joint.

Indication:

Varus gonarthrosis with axial malalignment

»

In the case of a X-legs malposition, the knee joint is overstressed on the outside. This often leads to arthrosis on the outside of the joint.

Indication:

Valgus gonarthrosis with axial malalignment

In the case of a X-legs malposition, the knee joint is overstressed on the outside. This often leads to arthrosis on the outside of the joint.

Indication:

Valgus gonarthrosis with axial malalignment

PROTECTED BY ORTEMA

Top athletes rely on our protective equipment.

»

Moto Cross / Denmark

Ortema made my first set of knee braces when I was 14 years old, and I never went on track without them again. Safety is extremely important in Motocross, and specially the knees are constantly in huge risk due to the changing terrain, ruts, bumps, jumps and putting out the leg in the corners. All 3 of my riders have a huge trust in their costum made Ortema knee braces.

Ortema made my first set of knee braces when I was 14 years old, and I never went on track without them again. Safety is extremely important in Motocross, and specially the knees are constantly in huge risk due to the changing terrain, ruts, bumps, jumps and putting out the leg in the corners. All 3 of my riders have a huge trust in their costum made Ortema knee braces.

»

Enduro / Great Britain

I have used several different brands in the past and i think that they all do offer some kind of protection, however it was not until i used ortema that i realised just how much support a knee brace can give. Only when you visit the headquarters and see the work and how much detail goes in to each product you can understand the quality and comfort.

»

NHL Player and National Player

The K-COM knee orthoses were part of my sports equipment, on both legs. The rails stabilised the joints without restricting my movement in any way. Thanks to their low weight and perfect fit, they are virtually unnoticeable during training and matches.

»

Ski / Germany

After tearing my cruciate ligament in 2013, the carbon brace from ORTEMA gave me the necessary safety and stability, which enabled me to stand on skis much earlier than expected. The brace was an important support for me both physically and mentally.In 2019 I suffered a shoulder dislocation in a fall. Thanks to a made-to-measure shoulder brace, ORTEMA made sure I could finish the season without surgery.After a short acclimatisation period, the orthoses gave me an enormously good and secure feeling, so I didn't want to be without them in training or races. At this point I really want to praise the team at ORTEMA, who are doing a great job and have supported me for many years!

»

Science + Technology DSV

For many years, Ortema has provided DSV with all manner of protective equipment as an important and dependable partner when it comes to the preventive care of our athletes. We have long since focused this partnership on the development and optimisation of a protective system for the knee joint. The resulting solutions are important components for our challenging goal of effectively reducing the risk of injury in ski racing.

»

Co-Trainer Los Angeles Kings / Former NHL-Player

Due to two cruciate ligament injuries within a very short time, I needed safety, confidence and stability. And I got all three thanks to a made-to-measure K-COM knee brace from Ortema. I was able to wear the light and sturdy brace with my ice hockey equipment without any problems and it was therefore perfect for my chosen sport.

PRODUCTION PROCESS

A plaster cast is made of the leg in the "original" to make an exact impression. The individual anatomy is recorded 100%. A plaster cast is used in cases of extreme axial deviations, for example, where a preliminary correction must be made.

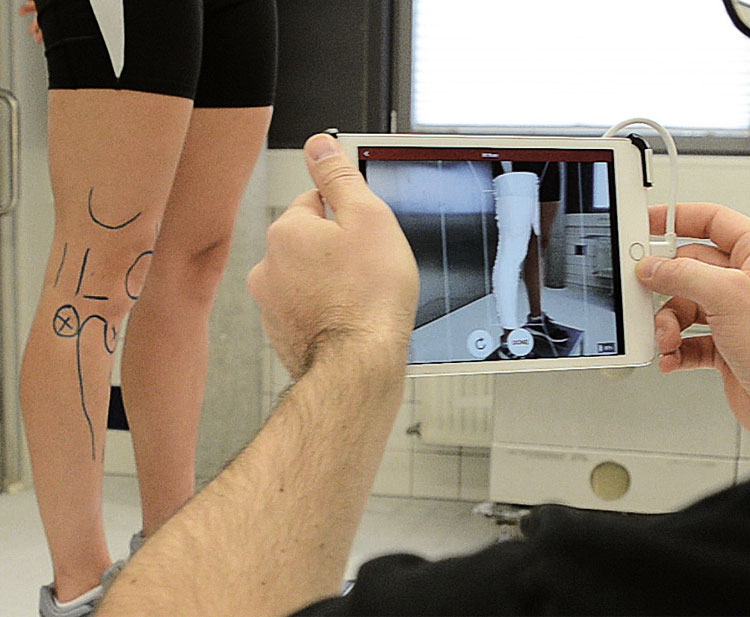

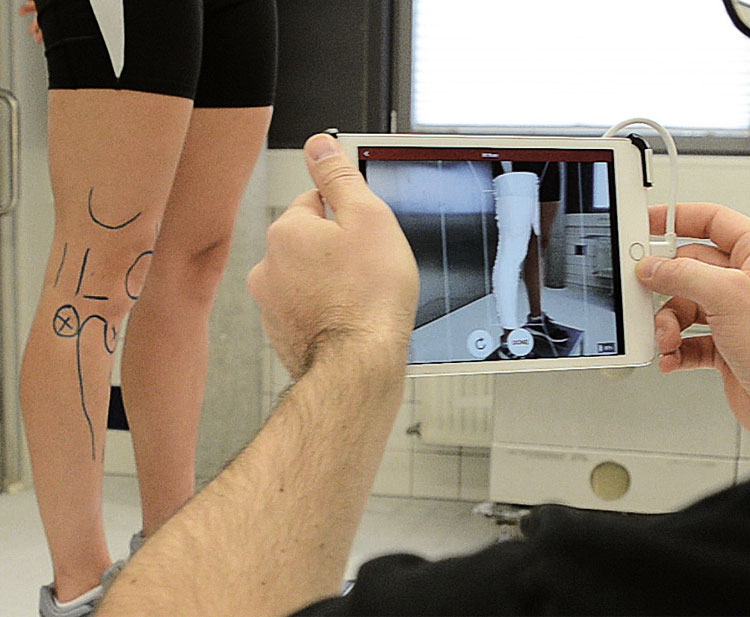

The 3D scan records the circumferences and lengths of the leg extremely accurately - the basis for the model technology. The advantages of 3D scanning are the fast data acquisition and data archiving as well as the elimination of the more time-consuming plaster cast.

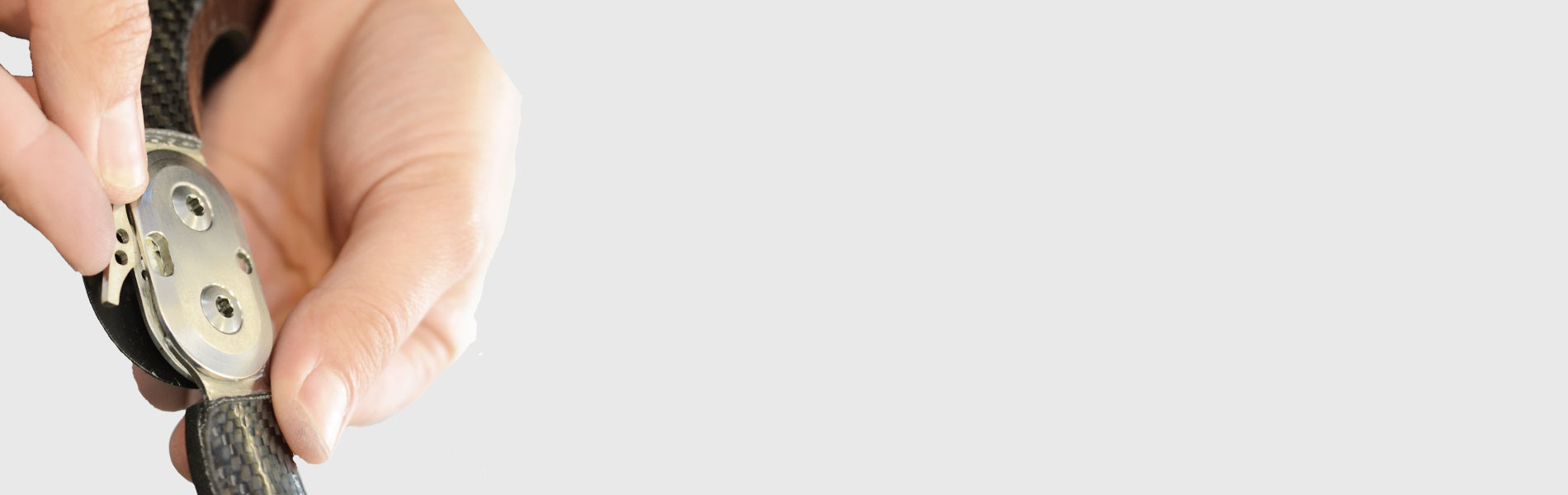

The joint splints are made of titanium. They are handcrafted into the carbon fiber reinforcement. This results in an extremely light and yet extremely stable construction.

During the fitting, the fit of the orthosis is checked and the customer is trained in the use of the orthosis. The fit is extremely important for stability and good fixation.

The K-COM knee orthosis is a high-quality medical product. It should be checked and serviced at annual inspections to protect the orthosis from wear and tear.

A plaster cast is made of the leg in the "original" to make an exact impression. The individual anatomy is recorded 100%. A plaster cast is used in cases of extreme axial deviations, for example, where a preliminary correction must be made.

The 3D scan records the circumferences and lengths of the leg extremely accurately - the basis for the model technology. The advantages of 3D scanning are the fast data acquisition and data archiving as well as the elimination of the more time-consuming plaster cast.

The joint splints are made of titanium. They are handcrafted into the carbon fiber reinforcement. This results in an extremely light and yet extremely stable construction.

During the fitting, the fit of the orthosis is checked and the customer is trained in the use of the orthosis. The fit is extremely important for stability and good fixation.

The K-COM knee orthosis is a high-quality medical product. It should be checked and serviced at annual inspections to protect the orthosis from wear and tear.

One-day Treatment

At our headquarters in Markgröningen we also offer one-day treatment. We make a plaster cast or 3D scan of your leg in the morning and fit the finished brace in the afternoon. We often do this for customers and athletes who are facing a longer journey to reach us. We have summarised all the key information about our one-day treatment. >> Info One-day Treatment

100% MADE TO MEASURE

FOR INJURIES OR MOVEMENT-INDUCED PAIN

The fitting of a K-COM knee brace can be beneficial after a ligament injury or for painful conditions such as arthrosis. The treating physician can issue a prescription for the brace together with all available diagnoses. After we have examined and advised the patient, we send the prescription and a cost estimate to the health insurance company. The health insurance company then checks that the costs are covered. Privately insured persons receive the cost estimate directly so that they can forward it to the insurance company themselves.

PREVENTION

If the brace is used preventively, for example to protect against injuries in sports, the costs for individual care must be borne by the customer. These are communicated to the customer after the examination and consultation.

SERVICE PRODUCTION

Our service manufacturing partner will provide you with the K-COM knee brace from ORTEMA

Our service manufacturing partner will provide you with the K-COM knee brace from ORTEMA.

Orthopedic technicians of the service partners cooperating with us are trained in the scanning process and plaster cast in our company. This enables them to have an individually manufactured knee brace made for you by ORTEMA.

Our experienced prosthetists carefully check the plaster cast or 3D scan sent to us. They then manufacture the K-COM knee brace according to the exact indication and the latest technical criteria.

After production and quality control, we send the brace to our service partner. The service partner's technician checks the fit and function of the brace and trains the patient in the use of the brace. The manufacturing process (plus shipping) takes a maximum of 5 working days.

Orthopedic technicians of the service partners cooperating with us are trained in the scanning process and plaster cast in our company. This enables them to have an individually manufactured knee brace made for you by ORTEMA.

Our experienced prosthetists carefully check the plaster cast or 3D scan sent to us. They then manufacture the K-COM knee brace according to the exact indication and the latest technical criteria.

After production and quality control, we send the brace to our service partner. The service partner's technician checks the fit and function of the brace and trains the patient in the use of the brace. The manufacturing process (plus shipping) takes a maximum of 5 working days.

DONNING INSTRUCTIONS K-COM

In addition to the fit, it is above all the correct donning and the correct fit that are decisive for the function of the knee brace. Our orthopedic technician master will show you how to put on the ORTEMA knee brace correctly and which mistakes to avoid.

TEST WINNER

among 14 of the most frequently used knee orthoses, in the TÜV report of the Basic Institute for Biomechanics of TÜV Munich

GERMAN SPORTS UNIVERSITY COLOGNE

Tested at the Institute for Biomechanics and Orthopedics, Prof. Dr. G. Brüggemann

EXPERIENCE

100 % INDIVIDUAL

& DEVELOPMENT

1000 TOP ATHLETES

KNEE ORTHOSIS TECHNOLOGY